Every object has its standards. Many people want to know the standards of sand blasting hose. Today, I will tell you about the standards and introduce related knowledge. The alias of sand blast hose is abrasive resistant hose for sand blasting. It is mostly used for air pressure sand blasting, rust removal and numbing on metal surfaces. It is also ideal for wet sand blasting and dry sand blasting. Thus it widely serves in mechanical process, ship building and spraying industry.

Classification of sand blasting hose

In general, shot blast hose has three types. The first type of is electrically connected and marked “M” grade. Then the second type is blast hose with a conductive rubber layer. While the third type is a non-conductive ordinary rubber hose, marked “A” grade.

Technical standards for shot blast hose

In terms of operating temp, the temp of sandblast hoses is -20-70℃.

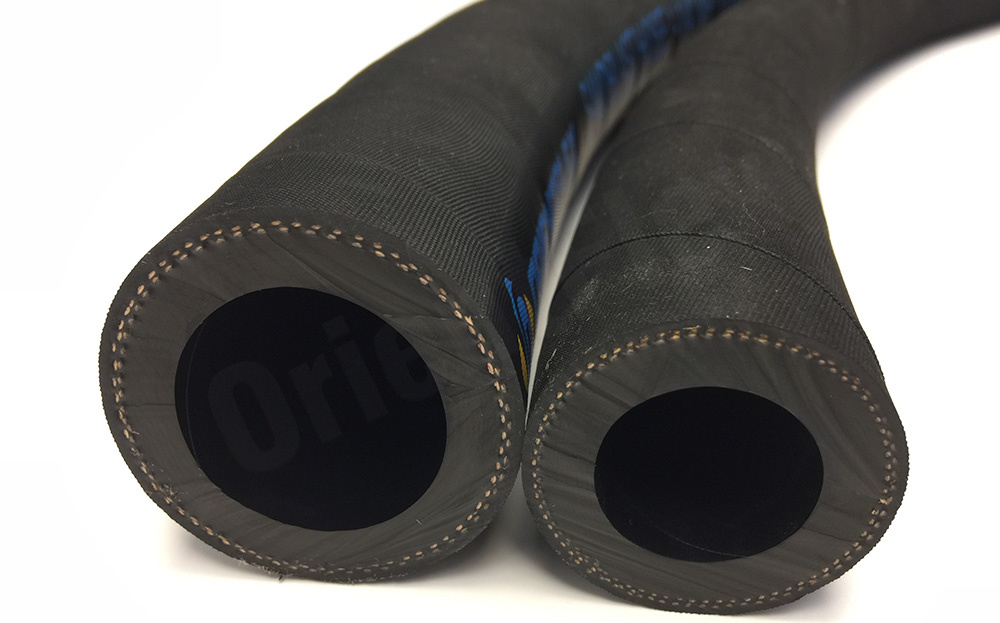

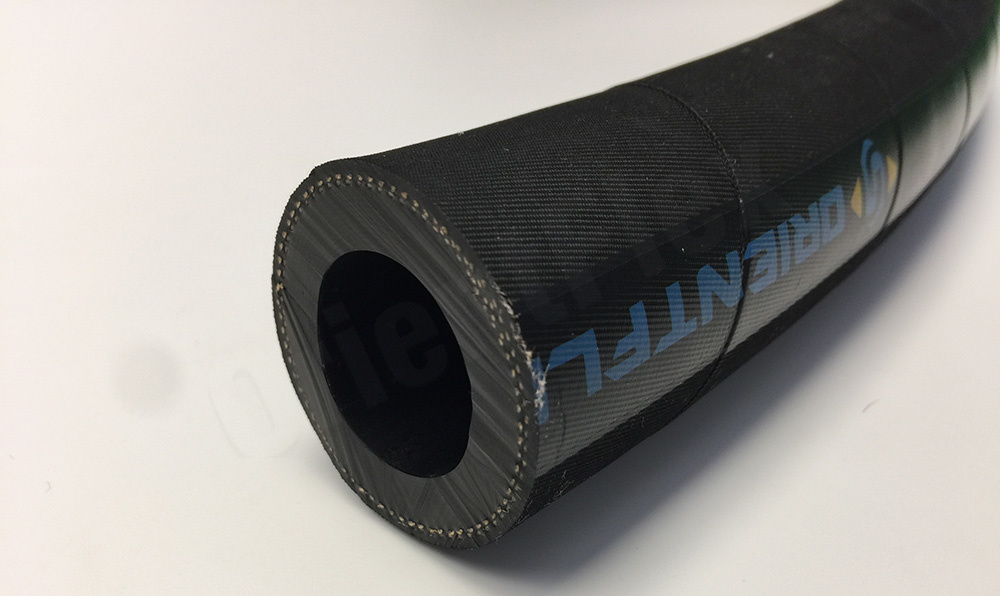

In terms of materials and structure, the blasting hose should have these parts. The first thing you need is an inner rubber layer. Second, there is a reinforce layer which consists of natural or synthetic materials. And it is mostly tape-cloth method and cord winding method. Besides fibre, there should be multi layers of steel wire. Third, it has an outer rubber layer.

As for the pressure, the max working pressure of the sand blaster hose is 1.2MPa. When you test it at 2 times of working pressure, there should not be water leakage. Besides, there can not be bulge and other abnormal situation. But for the anti-static hose, it must maintain pressure for one minute. At the same time, the length can not change by more than 0.8%. While the outer diameter can not change by more than 10%. Last, the burst pressure of the blasting pipe must not be less than 4 times the working pressure.