The sandblast hose plays an important role on the blast system. The blast hose is responsible for transferring the blast medium such as steel shots, sand, bead, etc. to the blast nozzle. It can be imagined that if the sandblast hose has any problems, the operators will face a significant safety issue. Thus, choosing a high quality and appropriate sandblast hose for your application is necessary. This piece aims to let you know the sandblast hose, guide you to choose the right sandblast hose , and provide you some suggestions on ensuring the operators’ safety.

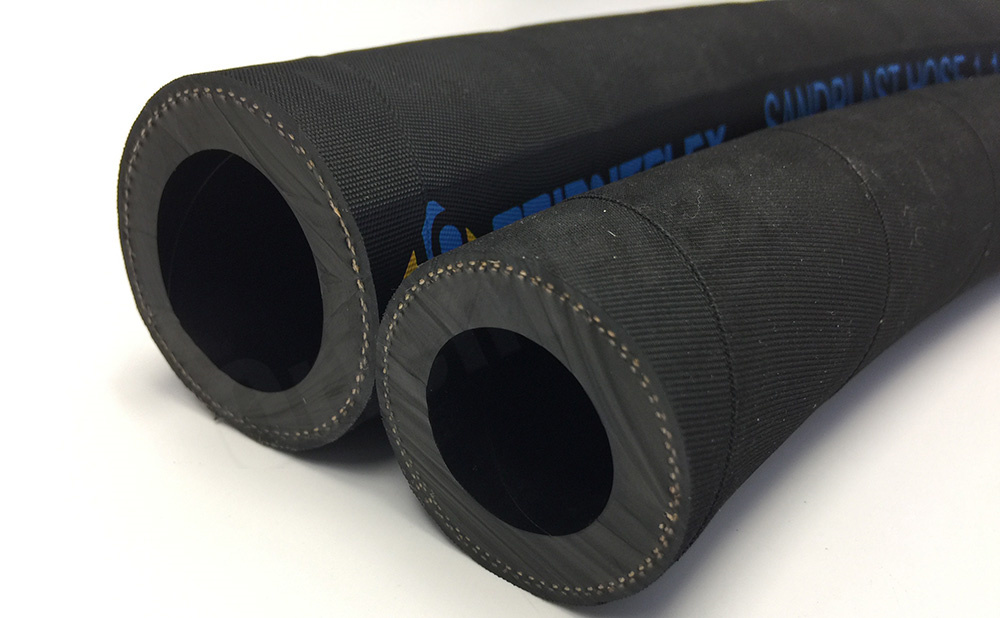

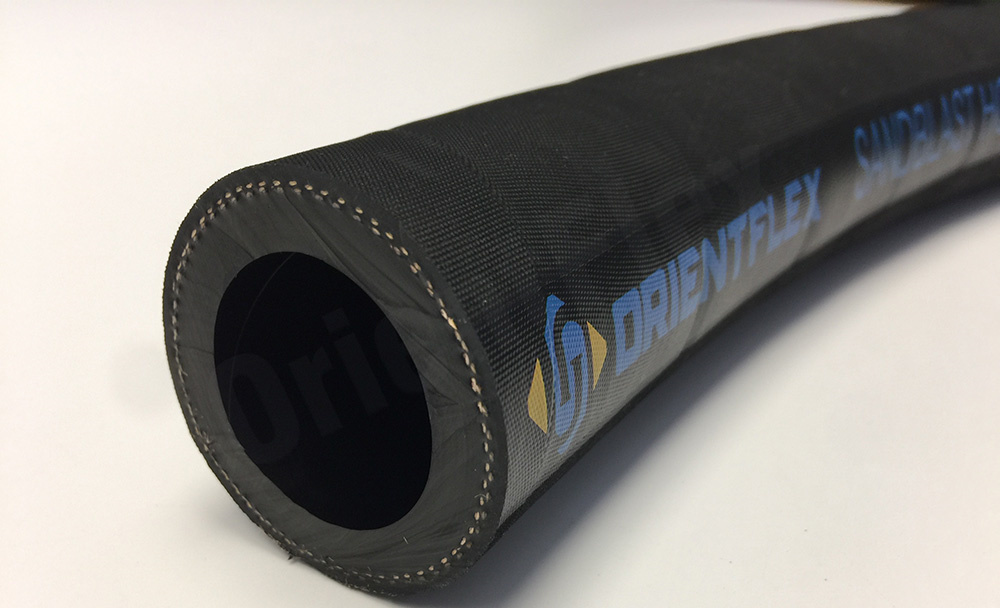

Firstly let’s see what the sandblast hose is. The sandblast hose constructed by a black and smooth synthetic rubber tube, reinforced by multi piles high strength synthetic fabric. And the hose’s cover is black abrasion resistant natural rubber or synthetic rubber. You can choose smooth or wrapped surface based on your preference. The reinforcement production process can adopt braiding or intertwining technology. Generally speaking, the sizes (I.D) are from 1/2″ to 1″, the hoses will adopt braiding technology, whereas the sizes are above 1″ to 6″, the reinforcement layers will be intertwined with 2 ply or 4 ply synthetic fabric. The hoses’ working pressure is 12 bar, the bursting pressure is the three times as the working pressure. The popular sizes are 25*38 mm and 32*48 mm (I.D*O.D), but you can decide based on your application requirements. For the 13-19mm size (I.D) of the hoses, the length can be made 50 and 100 meters. For the 25-102mm size (I.D) of the hoses, the length can be formulated 40 and 60 meters.

The sandblast hose are generally used to remove rust on metal surface by air pressure sandblasting. Due to the sandblast hoses’ application scenario, the hoses’ abrasion performance is important. The hoses’ abrasion loss value is the smaller, the better. There are three level of the sandblast hoses’ abrasion loss value, which are 60-75mm3, 110mm3, and 140mm3. Choosing the smallest abrasion loss value, the sandblast hose can reach the European standard. If continuity of conductivity is required, a cooper wire can be inserted into the sandblast hoses.

If you read till here, I believe you already knew some information about sandblast hoses. You might still have some concerns on which sandblast hoses will be proper and suit. For choosing the right sandblast hose, you might need to consider following factoring: the size, reinforcement layers, and the operation safety.

The size is one of the critical factors of blasting speed. The hose’s size should consist with the blast nozzle to provide adequate air and medium. If the hoses are too small, the media will go faster thus accelerate the abrasion. Orientflex can provide you the appropriate blast nozzle consisted with the sandblast hose. Or you have blast nozzles, we can help you find proper size of sandblast hose.

Concerning the reinforcement, more layers of reinforcement the hose will be stronger. Choosing more layers might increase the cost initially but the hoses will be better at anti-abrasion. If your application environment is strict 4 ply fabric reinforcement might be a prefer choice. 2 ply reinforcement is a popular choice for general industrial applications.

At last but important point is operation safety. The sandblast hoses will eventually wear and fail. Thus, it is necessary to check the signs of cracks, bulges or other problems of the sandblast hoses regularly and before each time operation. Besides the inspection of the sandblast hoses, a blast hose safety cable is necessary to prevent the potential risks. Notes, the safety cable should be used as straight as possible to reduce the hoses’ moving distance.

Choosing the right sandblast hose can help the operators to work efficiently and reduce the change frequency of sandblast hoses. If you need to find the sandblast hoses, let us help you to find the most appropriate hoses based on your requirements. Finally we wish you the best on everything.