During the storage of rubber hose, there will be many factors that can affect the hose. While these factors can cause aging and other problems. Next, let me introduce you

Ozone and oxygen

The product should be stored away from places where gas flows, especially vents. It must be stored in a closed space or box after packaging. Since ozone is very harmful to rubber materials, there should be no equipment that produces ozone in the storage room. For example, motors and other equipment that generates electricity or discharges. Combustion gases and vapors can also produce ozone through chemical reactions. Please note that arc welding produces high concentrations of ozone. Therefore, ensure thorough ventilation during welding. And the hose storage point should be far away from the welding operation area.

Stress

During storage, there should not be stress. Such as tension, pressure or other stress. Because stress can cause permanent deformation or cracks.

Packaging and contact materials

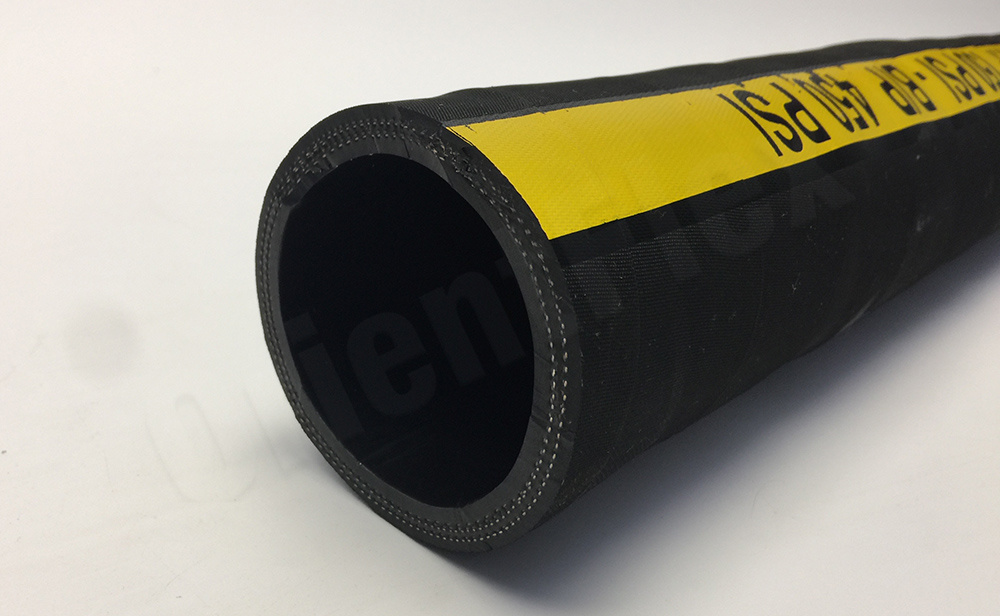

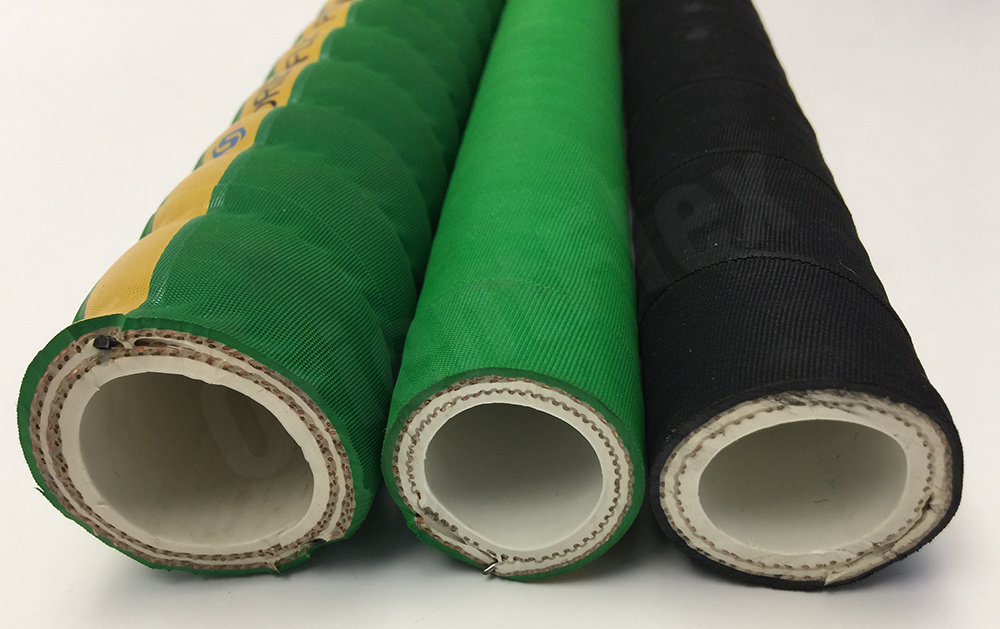

The packaging or covering must not contain substances that are harmful to the flexible hose. For example, copper or cuprous alloys, gasoline, grease and similar substances. Never use films that contains plasticizers as packaging material. Products with stainless steel reinforcement layers should be protected with anti-rust film. Or protect them with red or yellow coatings. Certain metals such as copper or manganese also have adverse effects on rubber products. Therefore, rubber hose should not come into contact with these metals. But you can protect the rubber pipe with other methods. Such as antistatic film, paper bag, nylon bag, etc.

Orientflex is your reliable one-stop supplier for fluid solution. Besides cost-effective hoses, you can also get relevant knowledge here. These include connection method, storage condition, types of fitting, etc. Contact us now and get the best purchase experience.