The production and manufacturing of lithium-ion batteries is a process that is closely connected with each process step. Overall, the production of lithium batteries includes the pole piece manufacturing process, battery assembly process, and liquid injection, precharging, formation, and aging processes. In these three stages of the process, each process can be divided into several key processes. Each step will have a great impact on the final performance of the battery.

In the pole piece manufacturing process stage, it can be subdivided into five processes. Slurry preparation, slurry coating, pole piece rolling, pole piece slitting and pole piece drying. The battery assembly process is roughly divided into winding, casing, welding and other processes according to different battery specs and models. The liquid injection stage also includes various processes such as liquid injection, exhaust, sealing, pre-filling, formation, and aging. The pole piece process is the core content of the entire lithium battery. Besides, it concerns the electrochemical performance of the battery. Among them, the quality of the slurry is particularly important.

Properties of lithium battery slurry

Lithium battery slurry is a non-Newtonian fluid and a solid-liquid mixed fluid. In order to meet the requirements of the subsequent coating process, the slurry needs to have the following three characteristics:

1. Good liquidity. Fluidity can be achieved by stirring the slurry and allowing it to flow down naturally. Then observe its continuity. Good continuity means good liquidity. Fluidity is related to the solid content and viscosity of the slurry.

2. Leveling. The leveling property of the slurry affects the flatness and uniformity of the coating.

3. Rheology. It refers to the deformation characteristics of the slurry during flow, and its properties affect the quality of the pole piece.

Lithium battery slurry transportation pipeline

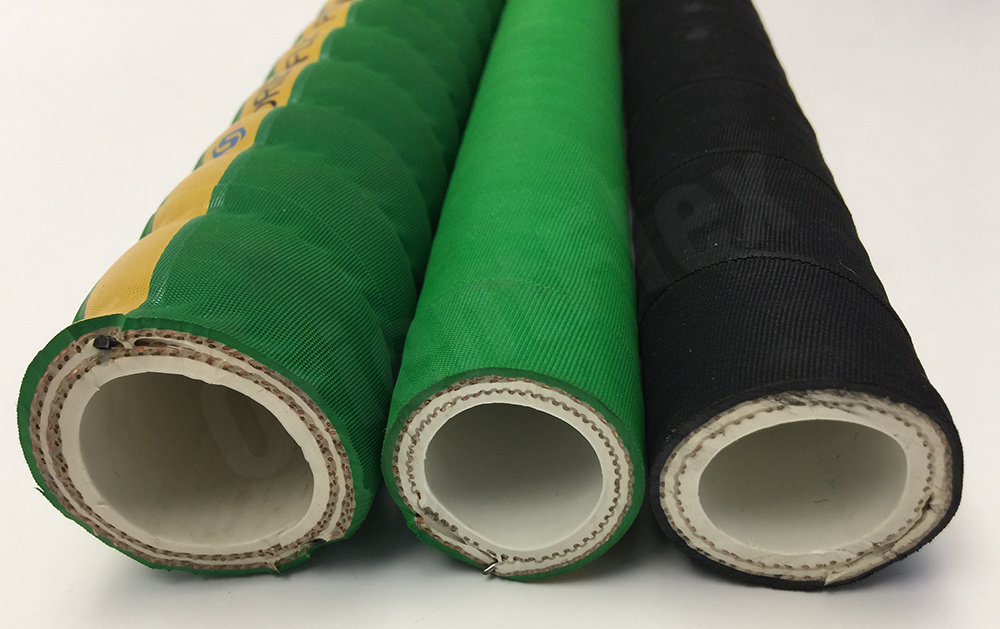

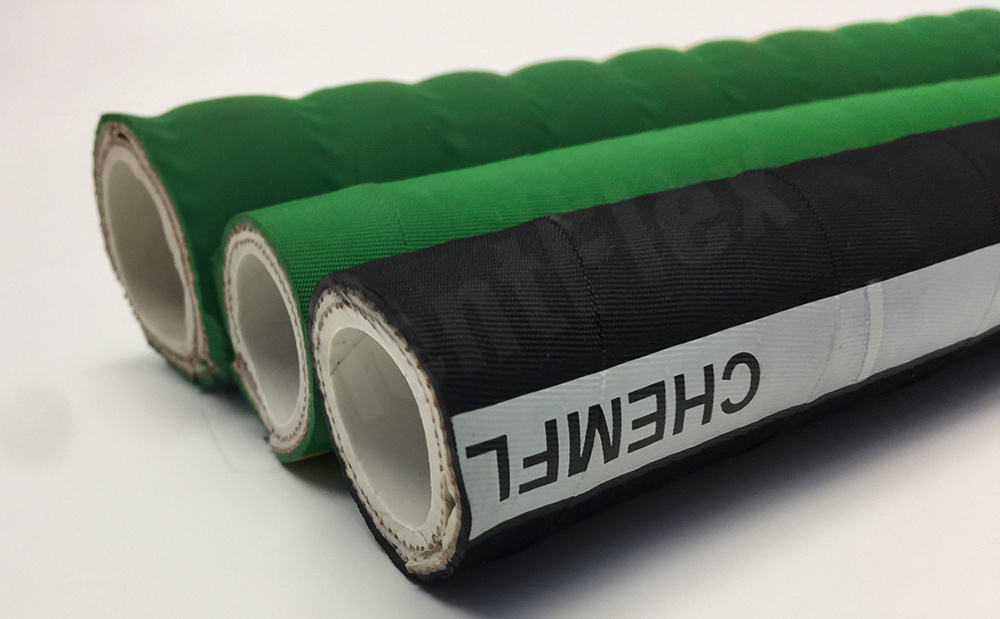

Orientflex recommends UHMWPE chemical pipe for you. It is a cost-effective hose that is ideal for transporting electronic slurry. It’s lined with translucent high-grade UHMWPE material. It can transport and pump a variety of battery slurry and chemical solvents with stable performance. UHMWPE chemical hose is wear-resistant, aging-resistant, oil-resistant, and chemical-resistant. Therefore it can be used in strict external environments. The inner layer is smooth, fully ensuring the fluid delivery flow. At the same time, a synthetic fiber braided mesh is used and reinforced with embedded spiral steel wires. Enables it to withstand working pressures up to 17bar/250psi. Safety guarantees the service life of the hose. It also has an operating temperature range of -30°C to +120°C. This attribute is also quite excellent among hoses of the same level.