The materials of acid and alkali resistant hoses include PVC, PP and PTFE. These materials have good acid and alkali resistance. Thus they can resist the erosion of various strong acid and alkali.

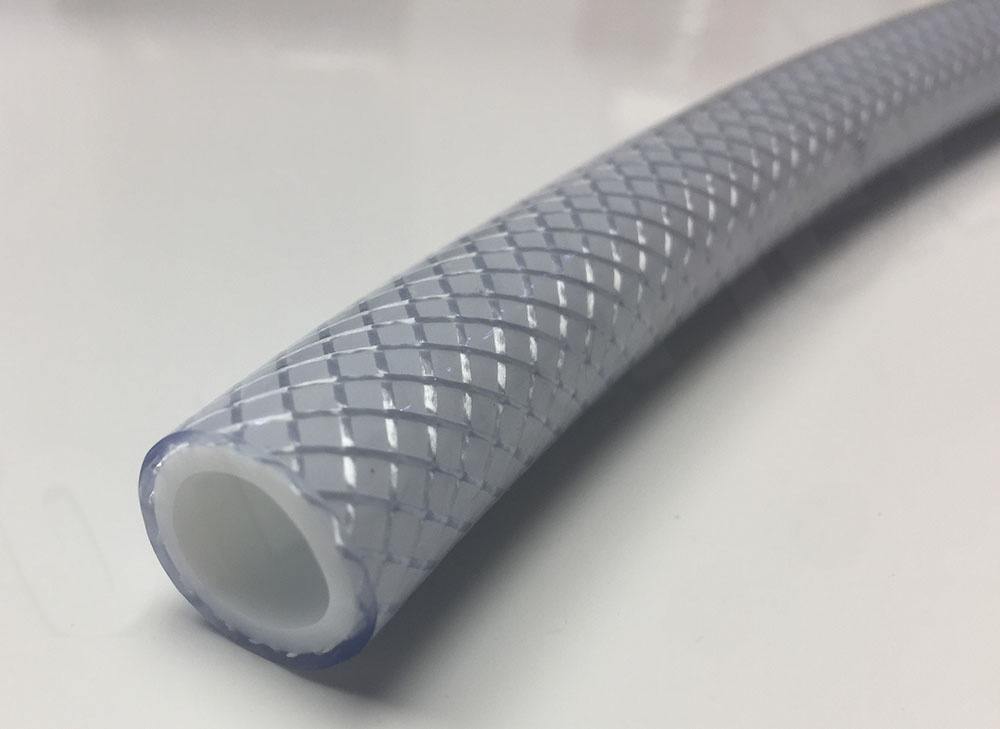

PVC hose

PVC hoses widely serve in chemical, food and many other industries. Because it has excellent chemical corrosion, wear and aging resistance. At the same time, the price is not that high. In addition, PVC hose is flexible with good stretch resistance. Therefore, it can reduce the impact of the equipment during the transfer process. In another hand, it has a long service life.

PP hose

PP hose has excellent corrosion resistance in high temp and high pressure. It also has high wear resistance, tensile strength and chemical stability. The inner wall of PP hose is smooth and the flow resistance is small. Therefore, it can reduce energy consumption and improve production efficiency.

Teflon hose

Teflon hose is also know as PTFE hose which has great value in the fields of electronic, electrical and aviation. Because it has excellent insulation property, high and low temp resistance and anti-adhesion property. Besides, it is stable in high temp, high humidity and high pressure. At the same time, PTFE hose has a lower coefficient of friction. Therefore, it can reduce the resistance and equipment wear.

These acid and alkali resistant hoses have their own features. For example, PVC hose will deform and release toxic at high temp. PP hose has poor tolerance under strong acid and alkali conditions. While PTFE hose is hard and not easy to bend and fix. Therefore, you should confirm the working environment first. Then choose the proper acid and alkali resistant hose material.