Orientflex Hose

PVC Hose

PVC hoses are flexible and light in weight. They widely serve in in dustrial and household applications.

Layflat Hose

Lay flat hose includes water hose, fire hose and air hose. It widely serves in fire fighting, water discharge and irrigation.

Hydraulic Hose

Hydraulic hose has various types like spiral hose, braided hose and thermoplastic hose.

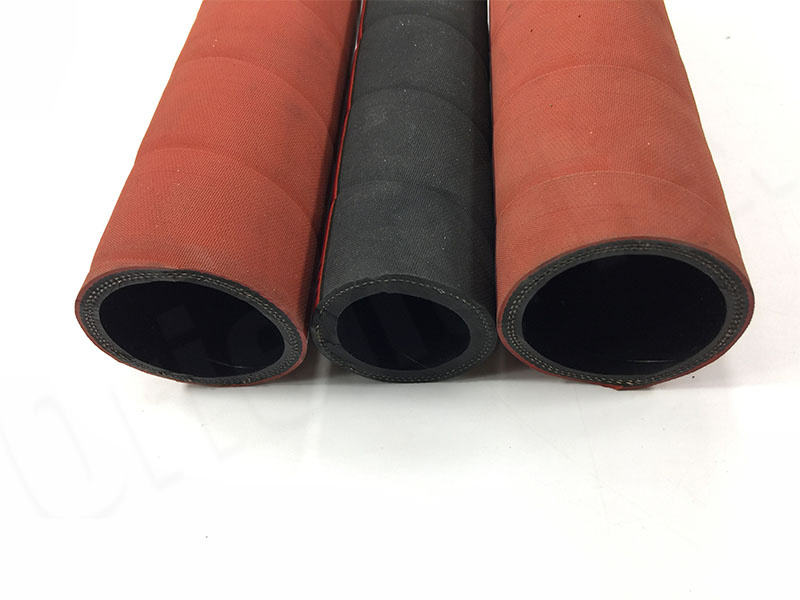

Auto Silicone Hose

Silicone hose for car includes elbow, reducer, hump hose, etc. They can resist high temperature in the engine.

Pneumatic Hose

Pumatic hose can be PU hose, PA hose and coiled hose. It is ideal for various of pneumatic tools and vehicles.

Duct Hose

Duct hose has 2 types. One is for material handing, while the other one is for air ventilation.

Hebei Orient Rubber & Plastic Co., Ltd is established in 2010. After 14 year’s development, we become a group company and change the name to Hebei Orient ADMA Tech Group Co., Ltd. Orientflex is a powerful company integrating research, develop and export flexible hoses and relevant fittings. Since set up, we always devote ourselves to offer you the most cost-effective hoses. For such purpose, we set up dozens of production line with professional engineer team and quality control team. Besides the quality, service is the other point that we always focus on. We have professional sales team and order tracking team to offer you the products and logistic solution.

As for the products, we offer you PVC hose, rubber hose, silicone hose, hydraulic hose, drilling hose, marine hose, etc. In a word, our hoses cover garden, agriculture, industry, mining, drilling, automobile and many other industries.

Why Choose Orientflex

Rich Experience

15 years’ experience in hose producing and exporting.

Professional Teams

Professional sale and support teams offer you the best purchase experience.

Strong Supply Ability

Orientflex has strong supply capacity, which could be 120 containers per month.

Complete Hose Series

Complete hose and fitting series cover all the industries.

Strong R&D Capacity

Strong research and develop capacity constantly bring you new products.

Flexible Payment

T/T, D/P, L/C and other methods make your payment flexible and diverse.

Competitive Price

Factory direct sale makes our price competitive.

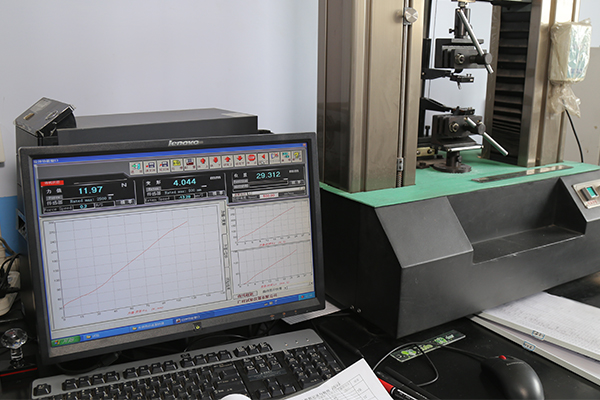

Strict Quality Control

Strict quality control system guarantees a 100% qualified hose product.

Worldwide Business

Our hoses has been exported to over 130 countries and receive good reputation.

Frequently Asked Question

How many kind of hoses do you supply?

Orientflex can offer you PVC hose, industrial hose, silicone hose, automotive hose, dredging hose, layflat hose, hydrualic hose, pneumatic hose, oilfield hose and duct hose.

Which kind of payment do you support?

We support T/T, D/P, L/C at sight or usance. While these methods makes your payment flexible.

Are you a manufacturer or a trader?

We are a manufacturer which has 15 years’ manufactuering and exporting experience. We offer you the factory direct hose and OEM/ODM service.

Do you supply custom hose?

Yes we can offer you suctom hose. You can just send us the drawing or OEM number, then we can customize for you.

Orientflex Business Step

Since set up in 2010, Orientflex has exported the hoses and fittings to all of the continents. While the our clients are from all over the world like America, Russia, Chile, Peru, Brazil, Thailand, Vietnam, Korea, Malaysia, Saudi Arabia, UAE, British, France, Germany, Italy, South Africa, Nigeria, etc.

Continents

Countries

Clients

Container/year

From Our Clients

Offering cost-effective hose products and attentive service are always our priority. And because of these, more and more clients choose us and trust us. Let’s see the good reputation from our clients.

Dear Eva and all team of Hebei Orient ADMA Tech Group Co., Ltd, thanks for your cooperation and hard work. Thanks for finding solutions during hard times. It’s a pleasure to deal with your company. Best regards from Russia.

We are glad to work with you and we know your company has good reputation in market. And you always think how to improve business. You have done a great service for us this year. Thanks for the effor. I’m looking to deepen the cooperation between our two companies.

Looking forward to continuing this beautiful relation ship. Really love working with the products. Feel very strongly about the future of your company and ours going forward. Keep in touch and waiting for my next order.

You always answer my question quickly and profesionally, you are available and helpful. You are the best company to work for. I seriously believed God brought you to my side and we are going to do very good business. I am enjoying my business relationship with you.

Leave Your Message

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 17332912071 or Email:orienthose@orientrubber.com.