Hydraulic Hose

Orientflex offers you both standard pressure rubber hydraulic hose and high pressure hose. As for the material, both rubber hose and thermoplastic hose are available.

Hydraulic Hose – International Standard

Hydraulic hose is a high pressure and flexible rubber hose to deliver hydraulic oils. While it is the most important part in a hydraulic system. Because the quality of such hose directvely determines if the system can work smoothly and effectively. Thus a reliable hose is very significant. While Orientflex offers you a series of high quality hose. We can offer you braided hose, spiral hose, thermoplastic hose and textile covered hose. Inquire the Direct Factory Price Now!

Braided Hydraulic Hose

Braided Hydraulic Hose Meets SAE Domestic and DIN International Standards, Our supply braided hydraulic hose is designed for medium to high-pressure applications and is constructed of the highest quality materials.

Spiral Hydraulic Hose

Spiral Hydraulic Hose is tested and approved for use in a number of industries throughout the world. All of our spiral hydraulic hose is manufactured to meet SAE domestic and DIN international standards.

Thermoplastic Hydraulic Hose

Thermoplastic Hydraulic Hose is manufactured to the highest quality standards. It features three-layer construction—nylon inner tubes, braided synthetic fiber reinforcement.

Besides standard hydraulic hoses, Orientflex also offers you hydraulic hose assembly. With advanced machines like skiving machine, cutting machine and crimping machine, our crimping accuracy can be several times than that of ordinary hoses.

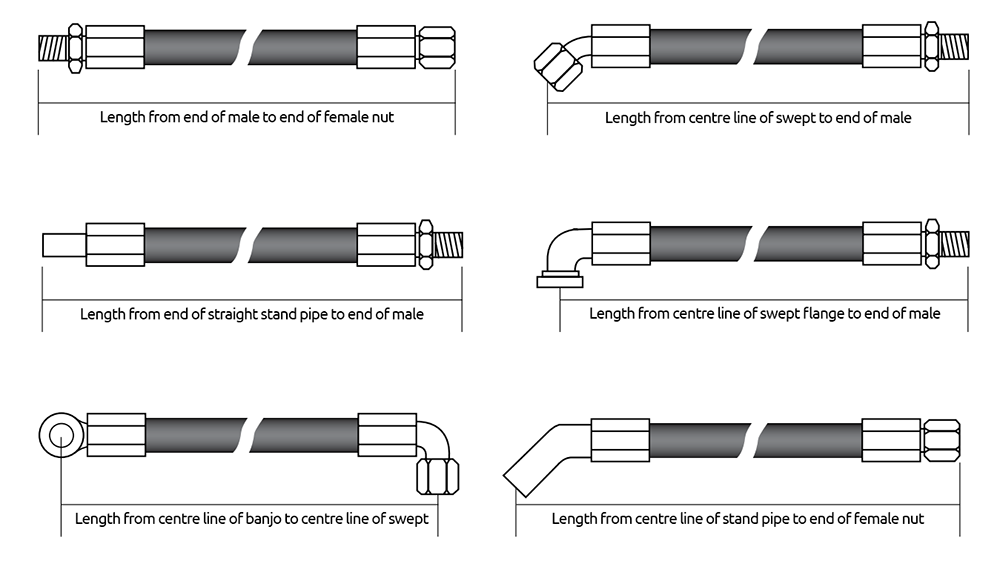

As for the hydraulic hose fittings, we can provide you various types like ferrule, flange, quick coupling, NPT, BSP, etc. While the material can be copper, stainless steel, etc.

Orientflex offers you customized service. While that means you can ask for any types of fitting with any lengths.

Related Products

Need a quote on Hydraulic Hose Assembly?

Send us your requirements

Orientflex can produce the high pressure hose according to different standards. First, SAE standard. While such hoses include SAE 100 R1, SAE 100 R2 and SAE 100 R14. Second, EN standard. While that includes EN 856 4SP. EN 856 4SH and EN 857 1TE. What’s more, we can offer you thermoplastic hose like SAE 100 R7 and SAE 100 R8 hydraulic hose.

As for the application, our hydraulic pipe is ideal for automative, construction, power plant, oil drilling, chemical, metallurgy and many other industries. Besides, it widely serves in various of machines like trailer, excavator, lift and many others.

Generally, the hydraulic hoses often works in a harsh condition with high temperature and potential wear. Thus we Orientflex offer you hose protecting sleeves to deal with such problem. We can offer you spiral guard and nylon sleeve to deal with the high temperature. Inquire the Direct Factory Price Now!

How Orientflex Control The Quality Of Hydraulic Hose

- Import the top grade raw material from Germany and Japan

- Introduce the advanced production equipment from Italy

- Supported by Korea and Italy technology

- The most reasonable formula

- Set up complete quantiy control system

- Set up professional and reliable quality inspection team

- Own over 150 professional and advanced engineer

- Set up advanced lab with advanced testing machinery

- Support the third party test

Features Of Hydraulic Hose

- High pressure resistant

- Weather and ozone resistant

- Abrasion resistant and durable

- Excellent oil resistant

- Long service life

- Any colors, sizes and prients can be customized

- Various types and standards are available

- Hydraulic hose assemblies are available

- Different types of connectors are available

- Ideal for various of applications like construction, automative, oil drilling and mechines.

Why Orientflex Is Your Unique Hydraulic Hose Supplier

- Produce the hose with top grade raw material

- Advanced production equipment bring you the high quality high pressure hose

- Various production standard meet all of your requirement

- Different types of hydraulic hose cover all the heavy industries

- One-stop service make you can get the food grade hoses and fittings

- Special OEM and ODM service make you can get the exact food safe pipe that you want

- Strong supply capacity (90 containers/month)

- Professional technical and sales team offer you the best solution

Good Reputations From Our Client

Rubber Hydraulic Hose Pipe Loading And Delivery

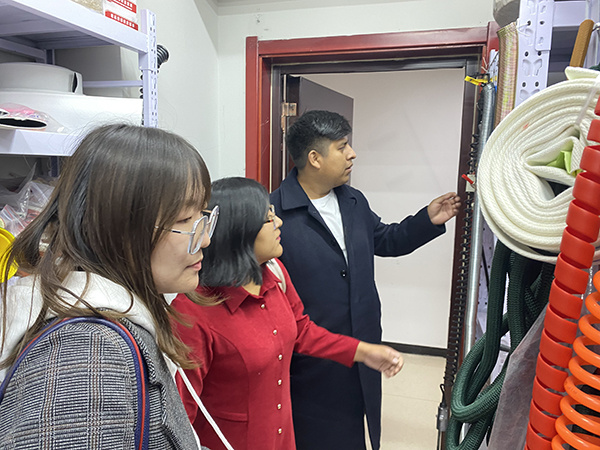

Client Visiting

Orientflex Exhibition Show

Leave Your Message

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 17332912071 or Email:orienthose@orientrubber.com.