Industrial Oil Hose

Advanced production equipment, reasonable formula and stric production standard make Orientflex industrial oil hose high quality. While the unique one-stop service will offer your the best purchase experience.

Industrial Oil Hose

Orientflex is a hose manufacturer with 17 year’s experience in producing and exporting flexible hoses. While our products include industrial oil hose, air hose, water hose, PVC hose, silicone hose, automotive hose, layflat hose and oilfield hose. Since set up , we set the goal to become a global one-stop supplier for flexible hoses and fittings. While that’s what we make every efforts to do.

Orientflex industrial oil hose almost contents all the oil industry. For general oil transfer and deliver project, an oil suction hose or oil discharge hose will suit you well. While for the petrol equipment, we can supply you fuel dispenser hose and gas station HDPE pipe. Besides, we can offer aircraft fueling hose which is a good choice for both civil and military use. But if you are doing the oil project between the ship and dock, our dock hose will be a good choice.

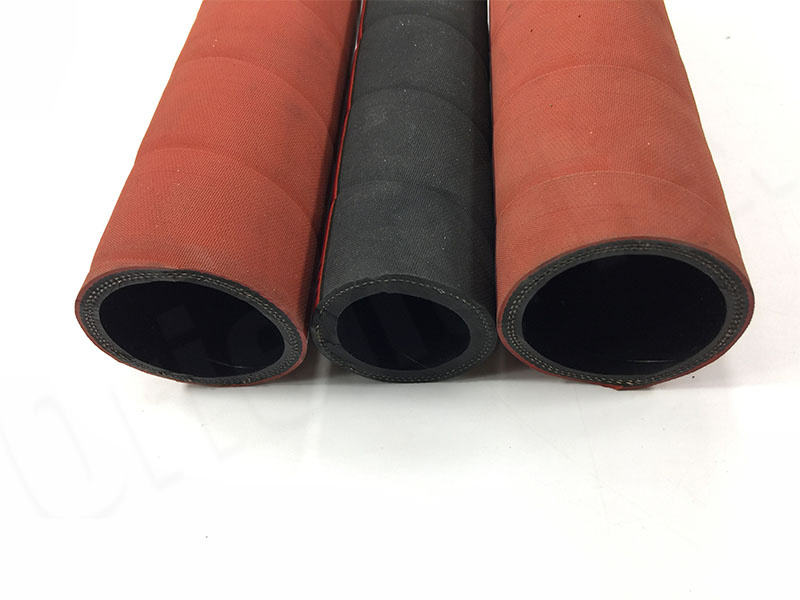

Nitrile Fuel Hose

Nitrile fuel hose is made from NBR which has the best oil resistance. Such rubber fuel hose can deliver petroleum, gasoline, fuel, diesel and many other oils.

Oil Suction Hose

Oil suction hose is reinforced with a steel wire layer and systhetic fabrics. Thus such rubber fuel line has excellent oil resistance. Besides, it can bear negative pressure.

Oil Discharge Hose

Oil discharge hose has a wide range of temperature which is -32℃-82℃. Such nbr fuel hose can transfer petroleum, gasoline, fuel, lubricant and other oils.

Dock Hose

Dock hose is a heavy duty oil transfer hose which mainly serves in dock and marine. It can deliver oil in the dock. While it can also transfer oil between the dock and ship.

Braided Fuel Hose

Braided fuel hose means that there is a textile cover on the hose. The textile cover can protect the reinforce layer from high temperature and external damage.

Fuel Dispenser Hose

Fuel dispenser hose is specially designed for fuel dispenser in gas station. It is to convey aviation kerosene, gasoline, diesel and other mineral oil.

Fracking Hose

Fracking hose is to transfer multiple types of hydraulic fracking fluids from tank trucks. The 6 plys of reinforce layer make such oil hose ideal for high pressure applications.

Fuel Drop Hose

Fuel drop hose is made of NBR with rigid PVC helix and embedded grounding copper wire. These make the hose more durable and protect you from static.

Aircraft Fueling Hose

Aircraft refueling hose is specially designed for aircrafts refueling. While it is resistant to fire, chemicals, ozone and weather. What’s more, it is also anti static.

Greasing Hose

Grease hose pipe is designed for grease gun and the working temperature could be reached to 5800 psi. While the burst pressure is 14500 psi

Lubricant Hose

Lubricant hose is mainly to deliver lubricant and other oils like grease, ediable oil and mineral oil. Such industrial oil hose belongs to thermoplastic hose.

Hot Tar And Asphlat Hose

Tar hose and asphalt hose are mainly to transfer hot tar and asphalt to the road construction site. Thus such rubber hose is abrasion and high temperature resistant.

LPG Transfer Hose

LPG transfer hose is to transfer liquid propane gas for both residential and commercial use. LPG hose remains flexible in cold weather.

Orientflex Industrial Oil Hose Advantages

Since set up, Orientflex always focus on the hose quality. Because for a rubber oil hose, the quality is everthing. A high quality oil rubber hose will not only makes your work smooth and effective, but also help ti save cost. Because a high quality industrial oil hose has a longer service life than the ordinary oil hose.

In order to offer you the best rubber fuel hose, we import the best raw material from Germany. With the top material and reasonable formula, our oil delivery hose has excellent performance. Besides, our oil resistant rubber hose is resistant to crack, weather and abrasion. What’s more, there will never be leakage problem. Thus our flexible oil hose is more durable with a long service life.

Because of the good quality and unique one-stop service, our industrial oil hose has been exported to over 100 countries. While we received good reputation from our clients all over the world. Your trust will always be our power to step forwawrd. Orientflex will always insist the win-win principle and will offer you the better and better industrial oil hose. Contact us now and start our business.

How Orientflex Control The Quality Of Industrial Oil Hose

- Import the top grade raw material from Germany and Japan

- Introduce the advanced production equipment from Italy

- Supported by Korea and Italy technology

- Constantly improve the formula

- Set up complete quantiy control system

- Set up professional and reliable quality inspection team

- Own over 150 professional and advanced engineer

- Set up advanced lab with advanced testing machinery

- Support the third party test

Features Of Industrial Oil Hose

- High pressure resistant

- Corrosion and chemical resistant

- Good air tightness

- Weather and ozone resistant

- Abrasion resistant and durable

- Long service life

- Any colors, sizes and prients can be customized

- Various types are available

- Ideal for all the processes in food industry

Why Orientflex Is Your Unique Industrial Oil Hose Supplier

- Produce the oil transfer hose with top grade raw material

- Advanced production equipment bring you the rubber oil hose

- Various production standard meet all of your requirement

- Different types of rubber fuel hose covers all the pneumatic industries

- One-stop service make you can get the air hoses and fittings

- Special OEM and ODM service make you can get the exact oil delivery hose that you want

- Strong supply capacity (90 containers/month)

- Professional technical and sales team offer you the best solution

Good Reputations From Our Client

Industrial Oil Hose Loading And Delivery

Client Visiting

Orientflex Exhibition Show

Leave Your Message

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 17332912071 or Email:orienthose@orientrubber.com.