Frequently subjected to strong working pressure shocks

The cracking of high pressure hoses is generally not caused by high static pressure. Instead, it is related to the intensity and frequency of working pressure shocks. When construction machinery and equipment are in operation, the steam pressure in the oil pipeline will continue to rise or fall suddenly. This will cause a pressure shock to the regular operation of the oil pipeline, causing the damage to the skeleton seals at various locations to increase. The hoses will bubble and crack, and the three-way joints will loosen and leak. Therefore, in actual operation, the rotation of the valve seat should not be too violent, but must be gentle.

The oil application temperature is too high

During the operation of construction machinery and equipment, the hydraulic transmission system heats the oil due to power loss. Coupled with the harm of the average temperature outside (especially in summer), the water temperature can be greatly increased. The higher the application temperature of the oil, the easier it is for the vulcanized rubber to become brittle. This will lead to a decrease in ductility, reduced compressive strength and sealing performance, and the high pressure hose will quickly rupture. Therefore, in work, when the hydraulic transmission system has a temperature rise that is too high or too fast, the cause should be checked in time and eliminated. Cooling measures should be taken for summer operations, especially for continuous operations.

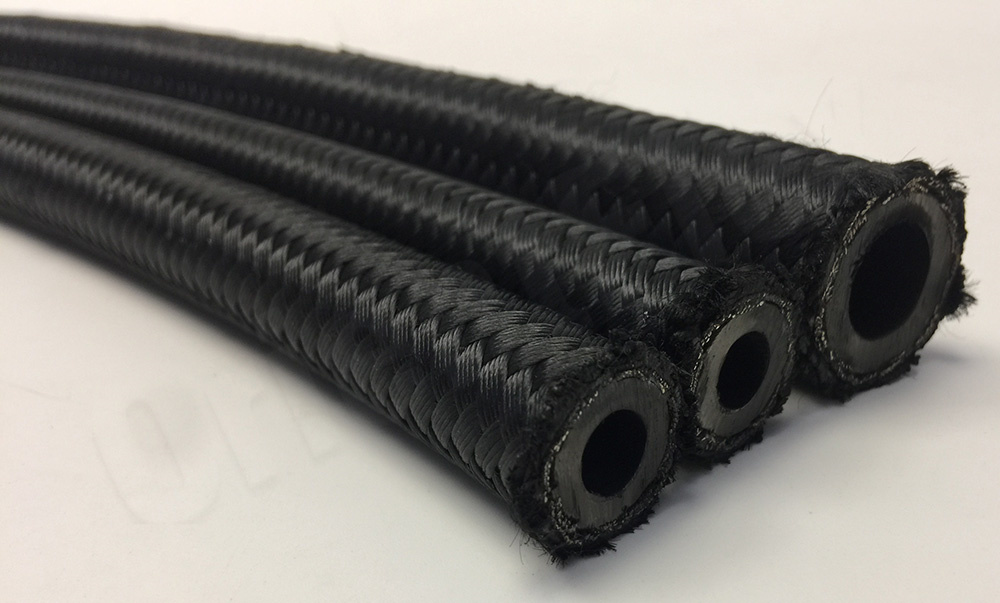

Unscientific use and installation of hoses

When disassembling and replacing high-pressure hoses, the hose length, number of stainless steel wire layers, connector shape and specifications are all effective. And the bending level of the hose should be minimized. When tightening the connector nut, the hose should not be distorted. Because excessive bending and distortion will greatly reduce the service life of the hose. Protective measures should be taken for some places that are prone to friction. To prevent the hose from breaking due to damage.